How is the wrinkle-resistant property of polyester fiber achieved through special processing technology?

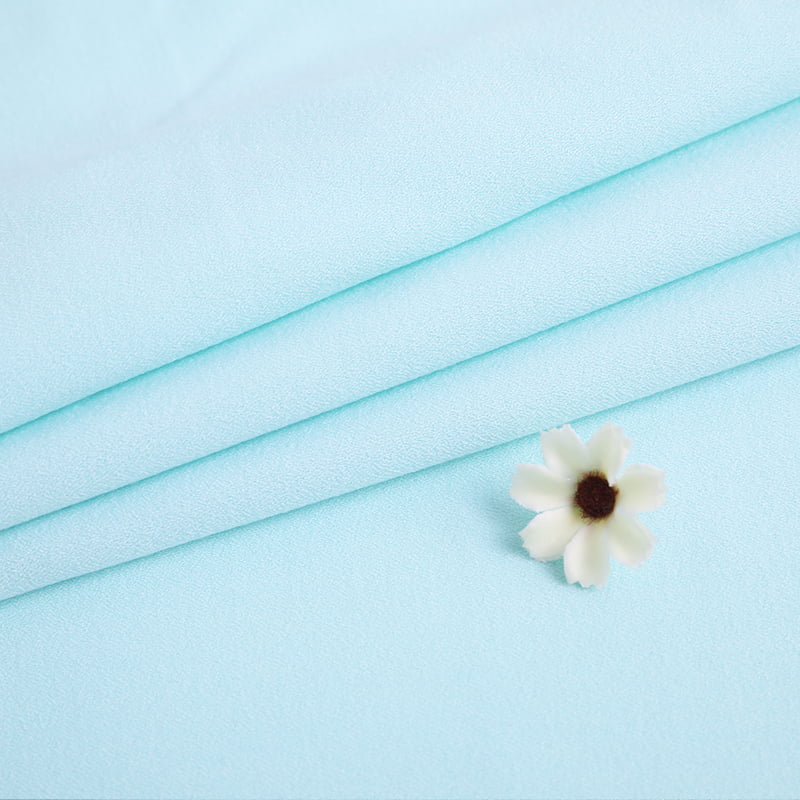

The wrinkle resistance of polyester fiber is achieved through a series of carefully designed and optimized special processing technologies, which not only retain the strength and elastic recovery of polyester fiber itself, but also further enhance its wrinkle resistance. The following is a detailed product knowledge introduction of these special processing technologies.

1. Yarn selection and preparation

The wrinkle resistance of polyester fiber is closely related to the quality and selection of yarn. In the production process, we use high-strength and high-elastic polyester yarns, which are specially treated to have better wear resistance and elastic recovery. By selecting high-quality yarns, we can ensure that the fabric maintains excellent performance in subsequent processing.

2. Weaving process

During the weaving process, we use advanced weaving technology to achieve a four-sided stretch design of the fabric by adjusting the parameters of the loom and the arrangement of the yarn. This design enables the fabric to quickly return to its original shape when subjected to external force, thereby keeping it flat and wrinkle-free. At the same time, we also improve the wrinkle resistance of the fabric by adding the number of horizontal and longitudinal intersections and increasing the yarn density.

3. Dyeing and finishing process

Dyeing and finishing processes are equally important for improving the wrinkle resistance of polyester fiber. During the dyeing process, we use reactive dyeing technology to closely combine the dye with the fiber to form a strong chemical bond. This technology makes the fabric colorful and has high color fastness, and it also helps to improve the wrinkle resistance of the fabric. During the finishing process, we use special anti-wrinkle agents to treat the fabric. These anti-wrinkle agents can penetrate into the fiber and form a stable bond with the fiber, thereby improving the wrinkle resistance of the fabric.

4. Anti-wrinkle performance test

In order to ensure that the wrinkle resistance of polyester fiber meets the predetermined requirements, we conducted a series of anti-wrinkle performance tests. These tests include elastic recovery rate test, anti-wrinkle grade test, etc. Through these tests, we can evaluate whether the wrinkle resistance of the fabric meets the standard.

The wrinkle resistance of polyester fiber is achieved through multiple links such as yarn selection and preparation, weaving process, dyeing and finishing process, and anti-wrinkle performance test. These special processing technologies ensure that polyester fiber fabrics have excellent wrinkle resistance and can remain flat and wrinkle-free for a long time, meeting consumers' demand for high-quality fabrics.

English

English 中文简体

中文简体 日本語

日本語 한국어

한국어 Español

Español русский

русский