How is rayon incorporated into double-woven fabrics?

In the textile industry, rayon, as a high-quality man-made fiber, is widely used in double-layer woven fabrics due to its unique properties. The clever integration of rayon into double-layer woven fabrics not only enhances the comfort and beauty of the fabric, but also enhances its environmental and sustainable properties. The following is an industry knowledge description of how rayon is added to double-layer woven fabrics.

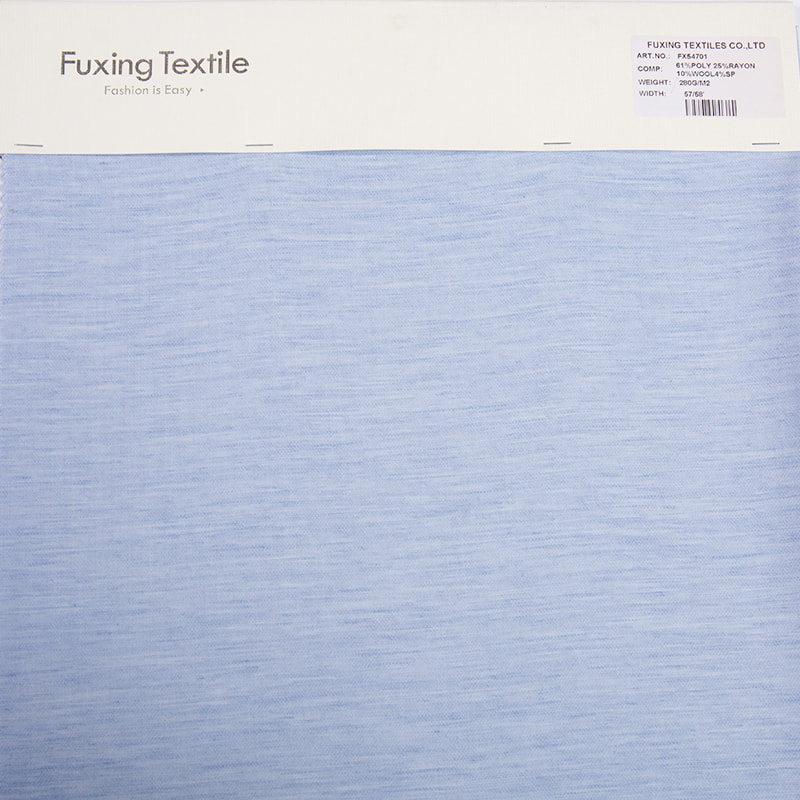

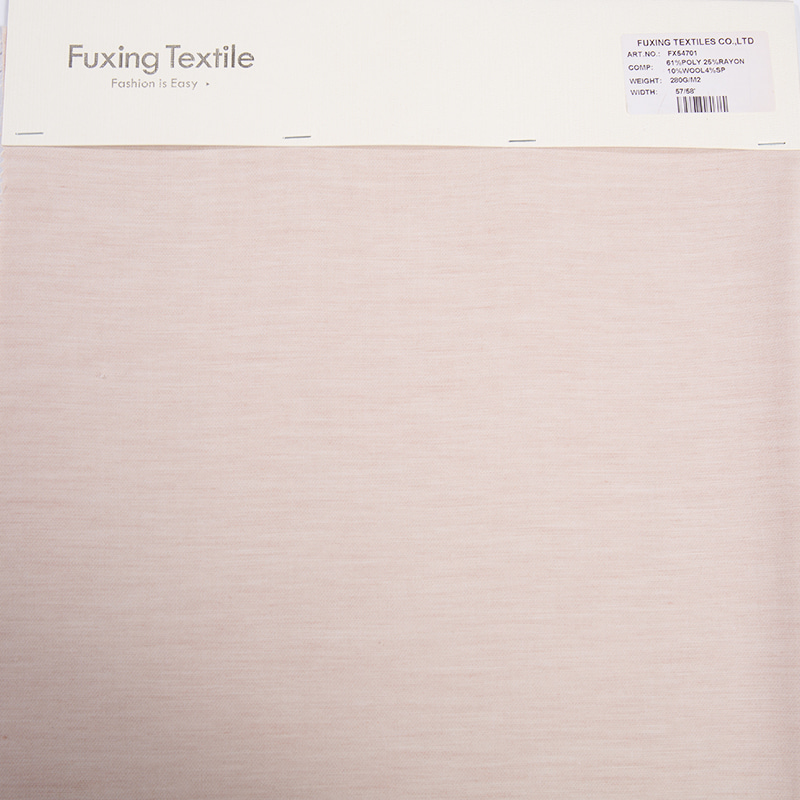

Yarn selection and preparation: In the production process of double-layer woven fabrics, the selection and preparation of yarns is a crucial step. For rayon, its softness, strength and hygroscopicity are subject to strict quality control. Manufacturers will select suitable rayon yarns according to design requirements and match them with other yarns (such as polyester, wool, etc.) to achieve the desired touch and performance.

Double-layer weaving process: The double-layer weaving process combines different types of yarns through a specific weaving method to form a product with a double-layer fabric structure. In the production process of rayon double-layer woven fabrics, rayon yarns are usually combined with other yarns by interweaving or stacking.

1. Interweaving: This method is to interweave rayon yarn with other yarns on a loom to form a double-layer fabric with an interwoven structure. Interweaving ensures that the rayon yarn is evenly distributed in the fabric, providing a uniform touch and performance.

2. Lamination: This method is to cover a layer of yarn with another layer of yarn to form a double-layer fabric by lamination. In the lamination method, rayon yarn is usually placed in the inner or outer layer of the fabric to provide a specific touch and performance.

Subsequent treatment: After the double-layer weaving is completed, a series of subsequent treatments are required to optimize the performance and appearance of the fabric. This includes dyeing, shaping, and finishing. During the dyeing process, rayon yarn and other yarns can be dyed different colors as needed to form unique patterns and styles. During the shaping process, the fabric can be made to reach the ideal size and shape through high temperature or high pressure. Finally, during the finishing process, the fabric can be trimmed, polished, etc. to remove excess yarn and impurities and improve the overall quality of the fabric.

Through the above steps, rayon can be successfully added to the double-layer woven fabric. This fabric not only has the advantages of rayon such as softness, smoothness and moisture absorption, but also combines the performance characteristics of other yarns to bring richer touch and beauty to textiles. At the same time, due to its environmentally friendly and sustainable attributes, this rayon double-layer woven fabric is becoming more and more popular in the market.

English

English 中文简体

中文简体 日本語

日本語 한국어

한국어 Español

Español русский

русский